Welcome to my project portfolio! Here you’ll find examples of my work in Robotics, Automation, and Mechanical Engineering. Each project showcases innovative solutions developed for various companies, from designing advanced robotic systems to creating efficient automation processes.

Automating Pharmaceutical Inspections with AI and Advanced Imaging

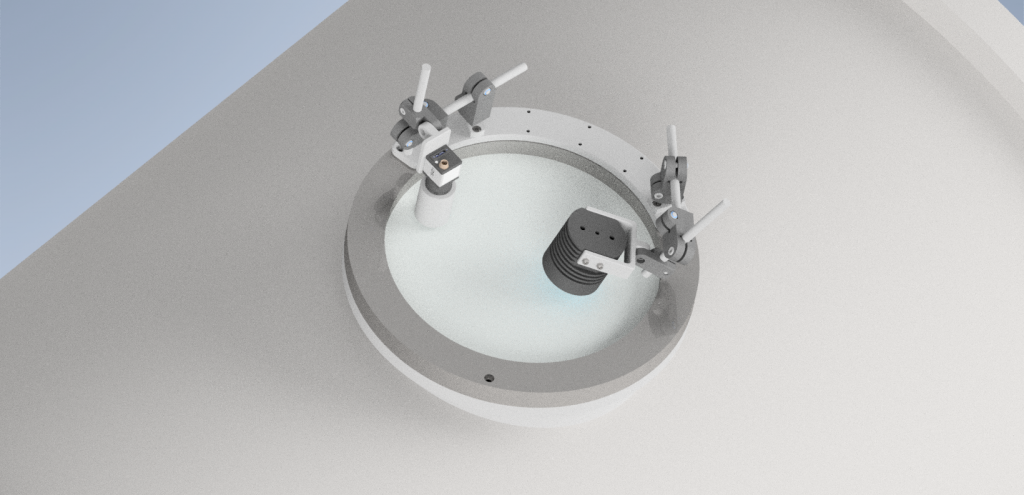

I collaborated with Data Spree on the „Artificial Intelligence Process Check“ project to automate manual inspections. We built the first prototype and developed a prototype of a gimbal solution to capture high-quality images inside the containers using the correct camera and lighting setup.

This allowed us to successfully complete the feasibility study, where even tiny contaminants were detected with greater accuracy than human inspection. This project marked a significant step forward in automating pharmaceutical processes.

Unmanned CNC machine loading

At motogadget, we developed an automated system to streamline the loading and unloading of milling machines. Our team integrated a Universal Robot (UR) to handle this task efficiently, reducing manual labor and increasing productivity.

By automating the process, we not only optimized production but also ensured consistent performance, enabling the system to handle batch sizes of up to 500 units with ease. This project marked a significant leap in automating our manufacturing processes, improving both precision and workflow.

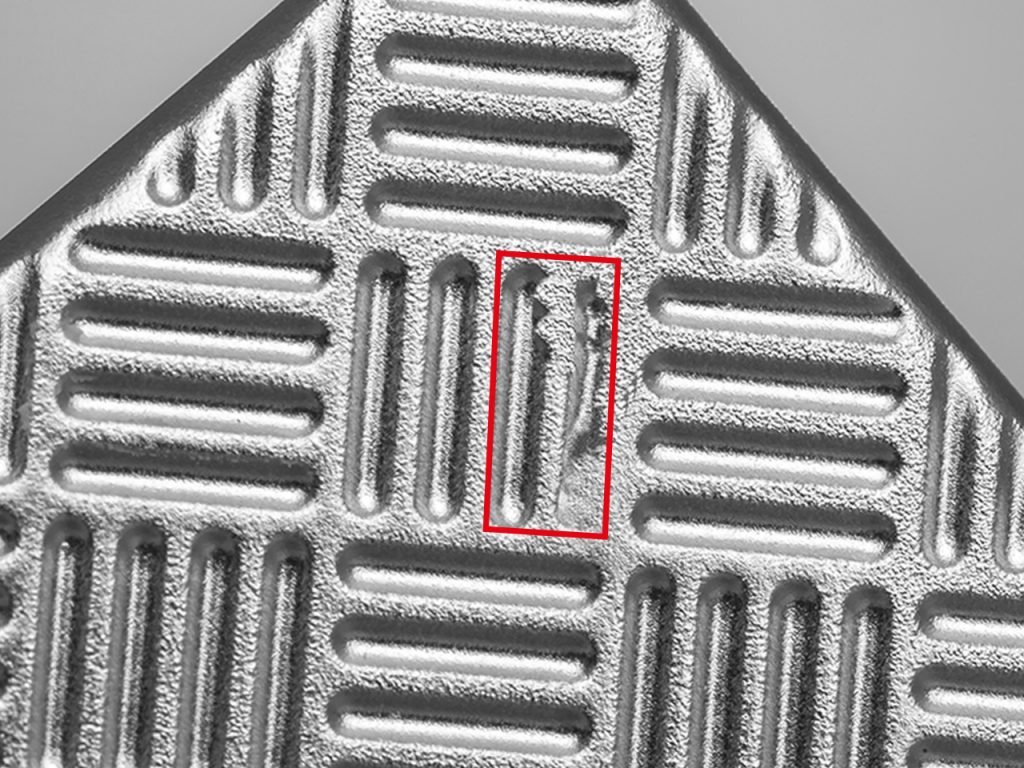

Inspection of highly reflective parts

A camera and lighting system was integrated into a production line to inspect highly reflective parts. The project utilized Data-Spree’s patented solution, which enables precise detection of defects on challenging, reflective surfaces. Traditional inspection methods typically struggle with these kinds of materials, but the advanced technology ensured accurate results.

This integration improved quality control and demonstrated how cutting-edge solutions can address complex inspection challenges in modern manufacturing.

AI-Powered Machine Monitoring for Enhanced Accuracy

In this project, we integrated a camera and lighting system into a production line to automate machine monitoring. I handled the hardware integration, ensuring optimal image capture, while Data-Spree GmbH developed AI algorithms to detect potential machine faults and irregularities. This solution significantly improved monitoring accuracy and efficiency, automating the detection of issues and reducing the need for manual inspections.