In the field of robotics, achieving seamless collaboration between humans and robots is a key challenge. While robots are incredibly effective at performing repetitive tasks with precision, they struggle with dynamic environments where adaptability is crucial. To address this gap, my latest research introduces a novel approach called Semi-Autonomous Teleimpedance, where the control of a robot is shared between a human operator and the robot itself. This system adjusts the robot’s stiffness (impedance) in real time based on visual input from an RGB-D camera that detects the object’s geometry and material.

Why Semi-Autonomous Teleimpedance?

Traditional teleoperation methods allow human operators to control robots remotely, but they require constant attention to detail, especially when interacting with objects of varying fragility or stiffness. In such cases, adjusting the robot’s physical interaction to avoid damaging objects becomes a complex task.

With teleimpedance, the robot can autonomously adjust its stiffness based on what it senses about the object, allowing the human operator to focus more on high-level control while the robot handles the physical nuances of each interaction. This not only reduces the operator’s workload but also improves precision and safety.

How Does It Work?

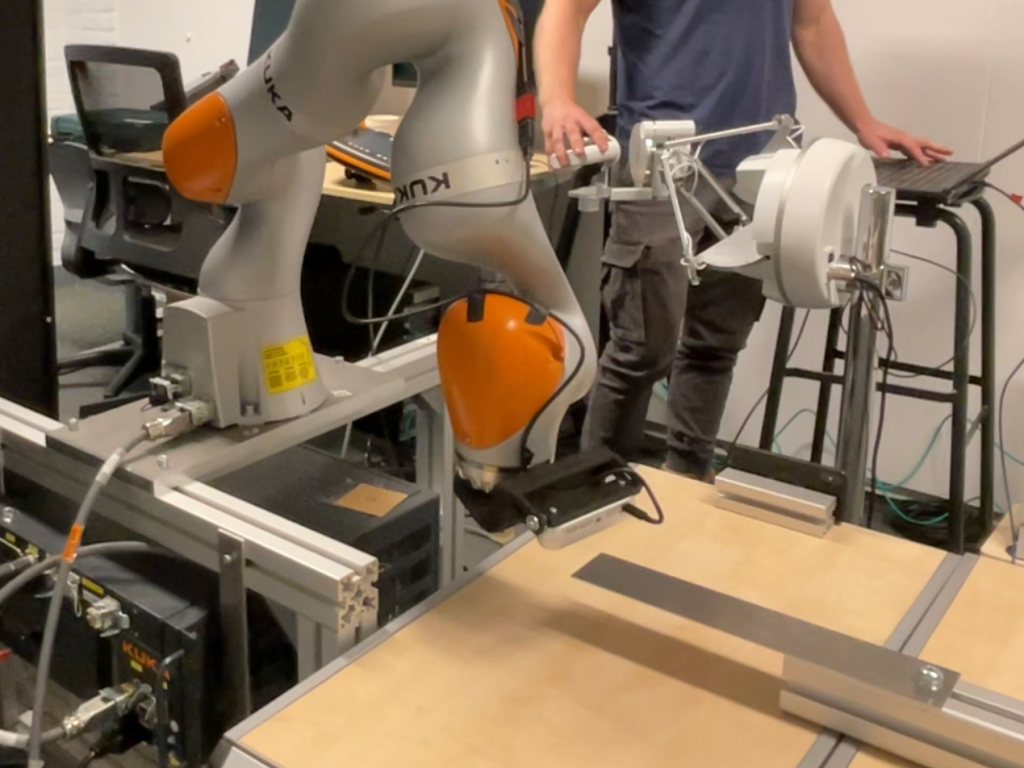

The key innovation of this method is the integration of an RGB-D camera close to the robot’s end-effector. This camera continuously captures the object’s geometry and material in the environment. The system then uses this information to calculate the appropriate stiffness the robot should apply when interacting with the object.

For example, if the robot needs to interact with a fragile object or a thin metal sheet, it will automatically reduce its stiffness to avoid bending or breaking the object. Conversely, for rigid or robust objects, the robot will increase its stiffness to apply more force.

Real-World Application

To validate the effectiveness of this approach, we tested it in two practical scenarios: bolt engagement and surface polishing. In the bolt engagement task, the robot successfully adjusted its stiffness as it moved closer to the bolts, preventing damage to the plate it worked on. Similarly, in the polishing task, the robot autonomously fine-tuned its stiffness based on the shape and material of the stripe it polished, demonstrating the adaptability of the system.

Both tasks showcased how the robot could dynamically adjust its impedance based on the geometry and material detected by the camera, reducing human intervention and ensuring smoother operations.

The Future of Human-Robot Collaboration

This research opens up exciting possibilities for human-robot collaboration, especially in environments where adaptability is essential. With further development, the system could be applied in various industries, from manufacturing to medical robotics, where the safe and precise handling of objects is critical.

As robotics continues to evolve, innovations like semi-autonomous teleimpedance will play a significant role in making robots more intuitive and efficient partners for human operators. By blending human intelligence with robotic precision, we are one step closer to creating truly autonomous systems that can handle complex tasks with minimal human input.