Ensuring accurate and reliable machine monitoring is a critical task in modern production lines. Manual checks can be time-consuming and prone to errors, which is why automating this process is essential for improving efficiency and reducing downtime. In a recent project, I worked on integrating advanced imaging technology and AI-driven algorithms to enhance machine monitoring accuracy.

The Challenge: Automating Machine Monitoring

Monitoring machine performance and detecting issues early is crucial to maintaining smooth production. However, relying on manual checks can lead to missed problems or delayed responses, impacting overall productivity. The challenge was to develop an automated system capable of consistently monitoring machines with precision, identifying potential issues before they escalate.

The Solution: Integrating Camera and Lighting for Optimal Image Capture

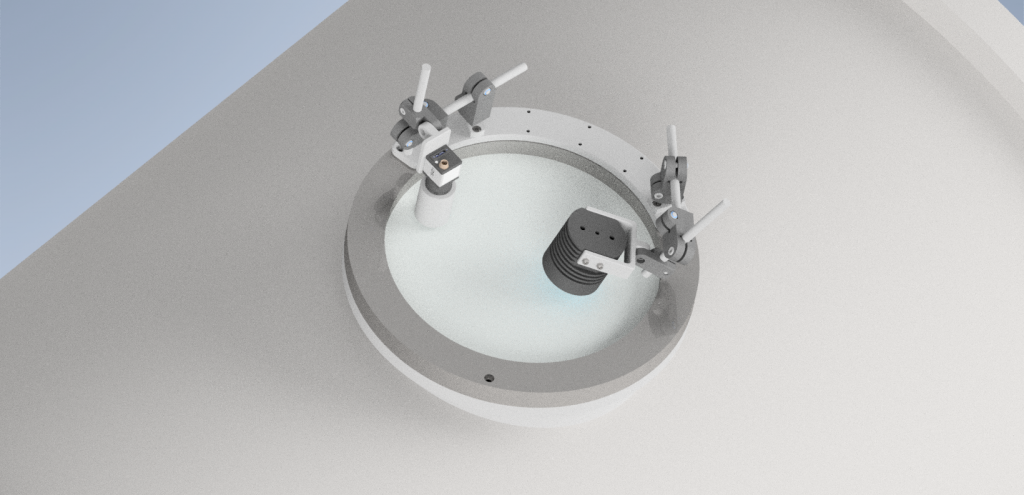

In this project, I handled the hardware integration, implementing a camera and lighting system designed to capture high-quality images of machine components and operations. By optimizing the lighting setup, we ensured that the camera could clearly capture the necessary details, while the AI algorithms analyzed the images to detect potential faults or irregularities in the machine’s performance.

The Results: Improved Accuracy and Efficiency

The integration of AI and advanced imaging technology significantly improved the accuracy of machine monitoring. The system automated the detection of issues, allowing for faster and more reliable responses. This not only reduced the need for manual inspections but also minimized downtime, ensuring continuous and efficient production.

The Future: Advancing AI-Driven Machine Monitoring

This project highlights the potential of AI-driven solutions in automating complex machine monitoring tasks. By leveraging advanced imaging and AI, we’ve demonstrated how these technologies can enhance production efficiency and prevent costly breakdowns. As automation continues to evolve, these solutions will become even more critical in maintaining high standards of operational performance.